The cable adopts chlorinated polyethylene process mainly for mixing, extrusion and vulcanization. The cable is made of chlorinated polyethylene.

I. Mixing process

1. The chlorinated polyethylene element does not contain double bonds in the main chain, and the process of mechanical plastics is difficult to cut, and it does not affect the viscosity of Mooney, so no mastication is required.

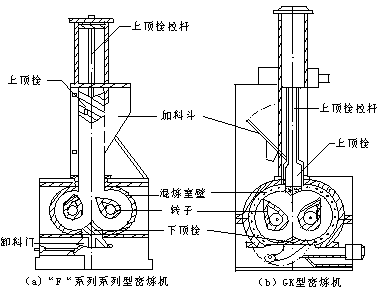

2. CPE glue can be mixed by an open mill, and it is also suitable for mixing with an internal mixer. Before mixing with an open mill, it is first necessary to confirm that the CPE is in the form of a powder. The CPE is first thinned to a translucent state on an open mill at 70 ° C to 90 ° C, and then kneaded. When the CPE glue is kneaded by an internal mixer, the temperature of the rubber compound should be kept between 30 ° C and 150 ° C. If the peroxygen is directly mixed into an internal mixer, the temperature in the internal mixer needs to be maintained below the peroxygen's 'sulfur' temperature. In addition, CPE glue requires sufficient packing capacity during the mixing process with an internal mixer, usually above 95%.

Extrusion

CPE has strong anti-scorch characteristics and can extrude a smooth and flawless cable. When the length-to-diameter ratio of the extruder screw is less than 12, the extrusion process will be more difficult. Hot feed extrusion is generally used to improve cable surface quality. If the aspect ratio is greater than 12, cold extrusion and hot extrusion can extrude a smooth and flawless cable product. Since CPS has fluidity, it has certain difficulties in plasticization. Therefore, the temperature of the fuselage during extrusion needs to be controlled within the range of 75 ° C to 85 ° C.

3. Vulcanization

CPE can be used for continuous vulcanization of pipes. In order to ensure production efficiency, it is very important to increase the temperature of vulcanization, and it is usually continuously vulcanized at 1.2 to 2.0 MPa. If the temperature is too low, the amount of the vulcanization system will be insufficient or the water cooling section will be too short, and there will be no cooling section, thereby forming bubbles. In addition, CPE is a heat-sensitive material that needs to be controlled in temperature during the extrusion and vulcanization process. If the temperature is too high, bubbles will form.